Infrastructure

Lenore Industries, one of the leading automatic machine manufacturers, is operating under the flagship of the Emirates Business Ventures Pvt. Ltd., functioning in Germany, headquartered in UAE with its principal office in India. Since 2000, Lenore has been an unrivalled manufacturing force in the industry producing superior quality products such as high-class machines, smart appliances, electrical and electronic products, institutional panels and machine tools. Lenoré strives successfully on a robust technical base, strongly supported by excellent R&D powers and a highly skilled workforce.

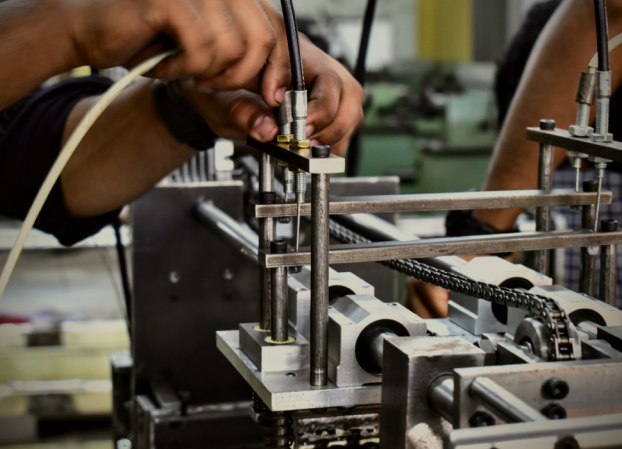

Mechanical Infrastructure

Lenore industries have an extensive and solidified mechanical infrastructure expanding over an area of 2000 sq. ft with more than 100 mechanical staff working with the sole aim of producing exceptional mechanical parts for our machinery with precision and accuracy. Our whole workspace is divided into various segments starting with a design section that consists of more than 10 design specialists fashioning authentic designs with computer-based simulation at every stage of design. Each and every design produced by the team is pretested and confirmed before starting on the mechanical prototype. Then comes the production team with our qualified professionals who builds every part of our product through high-quality machining skills. The mechanical production is monitored by more than 20 supervisors with high-end expertise in the field, inspecting the products at every stage of production. An average of 10 products are being manufactured per hour in Lenore workspace with a provision to facilitate continuous and batch production. Lenore mechanical plant employs an ergonomic design which makes waste management and recycling more optimal and ideal than ever.

Electronics Infrastructure

Lenore Industries holds a strong foundation of more than 30 professional staff collaborating together to make our top-notch circuits with the help of all the latest board manufacturing and testing equipment available. Our specialised research and production team of 10 staff designs each and every circuit board with accuracy. There happens a seesaw of suggestions and recommendations until the final design is drafted. Once the design is made, efforts are pooled in to create the product prototype. An electronic prototype serves as a product replica that undergoes diverse tests in its different facets such as functional testing, in-circuit testing, x-ray testing, advanced optical inspection which automatically analyses the PCB for defects etc. The ultimate goal of these advanced testing is to ensure that the product meets all safety precautions and quality standards. Once all the testings are done, the prototype is all set to be mass-produced. A separate section with a moist-free environment is allotted for the production process that makes Lenore circuit boards more impeccable. Our expert team conducts inspections at every stage of production to make Lenore circuits and products error-free and consistent.

Research and Development Highly Reliable & Affordable German-Class Technology!

Lenore Industries has always done remarkable investments in its Research & Development (R&D) field, to incorporate reliable, relevant, and High-Class Technology into our products, serving each and every one of our customers with standard technology. R&D has always been an area of prime focus and significance for us. Our research team consisting of highly-trained designers with notable credentials equips the company’s facilities with high-quality research technology. As a result of extensive research, our designers systematically get unified to develop unique and distinctive products that evidently makes our brand name “Lenore” stand out in the market.